Introduction – The Hidden Structures Behind Space Connectivity

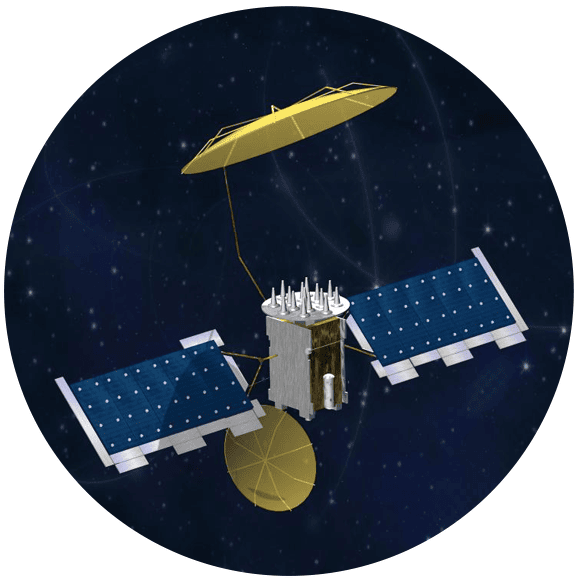

When we look up at the night sky, satellites are invisible to the naked eye, yet they are the backbone of global communication, Earth observation, and space exploration. At the heart of these spacecraft systems lie components that few outside the industry ever hear about. One of the most vital is gold-plated molybdenum wire, a material engineered into ultra-lightweight meshes that unfold in orbit to form large-scale space reflector antennas. These self-deployable satellite reflectors allow data to flow across continents, enable soil moisture mapping, biomass estimation, and even provide the foundations for future space-based internet services.

Why Gold-Plated Molybdenum Wire?

In designing space systems, every gram matters. Molybdenum is favored over tungsten because it offers a lower density—roughly half the weight—while still providing excellent mechanical strength and ductility. This weight advantage is crucial during launch, where reduced payload mass directly translates to lower costs and increased efficiency.

Gold plating further enhances the base wire by delivering:

Superior corrosion resistance during ground handling and deployment.

Enhanced RF reflectivity, critical for transmitting and receiving high-frequency signals.

Excellent solderability and surface conductivity, ensuring reliable integration with satellite structures.

The result is a wire, gold-plated molybdenum wire, that is lightweight, strong, and highly conductive—exactly what self-deployable space reflectors demand.

From Fine Wire To Antenna Mesh

Transforming gold-plated molybdenum wire into a working reflector system is an engineering art. Customers and subcontractors use warp-knitting techniques—a process that blends weaving and sewing—to create large, lightweight meshes. The process requires precision in cutting, joining, tensioning, and shaping. Learn more about innovative debloyable antenna frames at ESA.

These meshes are not ordinary textiles. They are engineered structures designed to retain their form under the harshest possible conditions. Diameters of the woven mesh can range from 1.5 meters to over 20 meters. For instance, a 19 × 17 meter antenna mesh can be stowed compactly at just 1 × 4 meters for launch. Once deployed in orbit, it regains its full surface geometry, maintaining accuracy within millimeters.

Performance in the Harsh Space Environment

Operating in orbit is a brutal test for any material. Reflector meshes made of gold-plated molybdenum wire must endure:

- Thermal fluctuations from –150 °C in shadow to +150 °C in sunlight.

- High-energy radiation that can degrade unprotected surfaces.

- Micrometeoroid impacts and atomic oxygen exposure.

- UV intensity far greater than on Earth.

Gold-plated molybdenum wire combines elasticity with thermal stability, making it resilient against these stresses. The gold coating—typically constituting at least 1% of the wire’s diameter—ensures corrosion protection and supports long-term performance. Typical wire dimensions for reflector meshes range between 20 and 40 microns, thinner than a human hair yet strong enough to form vast, precise structures. Learn more about how to optimize large mesh for large deployable reflectors .

The Precision Behind Radio Frequency (RF) Performance

The reflector’s ability to accurately transmit and receive signals depends on both the consistency of the wire diameter and the uniformity of the gold coating. LUMA Wire Tech’s proprietary plating processes used for their gold-plated molybdenum wire deliver micron-level accuracy, ensuring reliable RF characteristics across large mesh panels. This precision is especially important as satellite communication moves to higher frequencies.

The Precision Behind Radio Frequency (RF) Performance

The demand for higher-frequency communication, such as V-band systems operating between 40–75 GHz, is growing rapidly. These frequencies enable massive data transfer but require finer mesh openings to ensure accurate reflection of RF signals. As antenna systems become larger and more advanced, the need for high-quality gold-plated molybdenum wire only increases.

Deployable reflector systems made with this technology are central to several key developments:

Earth Observation – monitoring soil moisture, vegetation biomass, and climate indicators.

Telecommunication – supporting global connectivity and bridging digital divides.

Next-generation space internet – delivering broadband access from orbit.

Luma Wire Tech´s Role as a Trusted Supplier

Luma Wire Tech has established itself as the only European producer of gold-plated fine wire for deployable antenna meshes. With more than 90 years of expertise in fine wire manufacturing, Luma Wire Tech is a trusted partner to satellite manufacturers worldwide. The company’s competitive edge lies in its ability to customize according to strict customer specifications—meeting exacting standards in tensile strength, coating adhesion, and dimensional tolerances.

By combining proprietary electroplating technology, advanced quality control, and sustainability-driven processes, Luma Wire Tech ensures each spool of wire can withstand the most demanding aerospace requirements.

Conclusion – Precision in Every Micron

Space missions depend on precision, reliability, and materials that simply cannot fail. Gold-plated molybdenum wire is not just a material—it is the hidden enabler of communication systems that connect the world, observation platforms that monitor Earth’s health, and future satellite networks that promise universal connectivity.

As satellites continue to grow in scale and performance, and as communication frequencies push ever higher, Luma Wire Tech’s fine wire solutions will remain at the heart of innovation. From warp-knitted reflector meshes to the next generation of deployable antennas, gold-plated molybdenum wire ensures that humanity’s signals reach across the skies—precisely, reliably, and sustainably.

How can we help you choosing the right wires for your application?