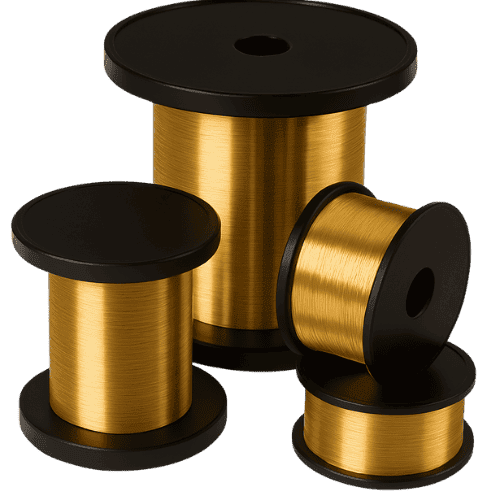

Our gold plated molybdenum wire combines low weight, excellent conductivity, and exceptional reliability. Engineered for aerospace, satellite, and high-frequency electronic systems, it offers the strength and ductility needed in weight-sensitive, high-precision environments. With superior solderability and corrosion resistance, our gold-coated molybdenum wires maintain consistent performance even after exposure to extreme heat and radiation. Each wire is manufactured in Sweden with proprietary precision techniques for unmatched surface quality.

Aerospace

Lightweight mesh antennas

Medical

Neurostimulation

surgical robotics

Sensors

R&D instrumentation

Electronics

Wire bonding – microchips

fine wire for technical research and development

fine wire for technical textiles

fine wire for digital printing and ion generators

Fine wire for lightning industry

Do you want to discuss technical features with our Technology Team?

Luma’s gold plated molybdenum wires are trusted across a wide range of advanced industries where performance cannot fail:

Molybdenum is valued for its low density (10.22 g/cm³), which makes it approximately half the weight of tungsten. This weight advantage is critical during space launches where mass drives cost. Combined with gold plating, molybdenum wire achieves:

Elasticity and tensile strength suitable for deployable reflector meshes.

Reliable conductivity across Ku-, Ka-, and V-band frequencies.

Durability in long-term orbit with resistance to thermal cycling and radiation exposure.

These properties make gold plated molybdenum wires the benchmark for reflector mesh technology and other weight-sensitive, high-reliability applications.

If you require gold plated molybdenum wires for aerospace, satellite, or advanced electronic applications, Luma Wire Tech is your trusted partner. Our technical experts are ready to support you in selecting the right dimensions, coatings, and finishes for your project.

Contact us today to discuss how our fine wire solutions can support your next mission.

What are the advantages of gold plated molybdenum wire compared to pure tungsten?

Molybdenum offers lower weight while maintaining high tensile strength. With gold plating, it also achieves superior corrosion resistance and RF performance.

How does gold plating improve performance?

The gold layer prevents corrosion, enhances conductivity, and improves long-term durability, especially in extreme environments like space.

What diameters are available?

Luma supplies gold plated molybdenum wires in diameters from 5 to 200 microns, with custom plating thicknesses available on request.

Is Luma Wire Tech ISO certified?

Yes. All our wires are manufactured in Sweden under strict ISO-certified and ESG-compliant processes, ensuring traceability and quality.

Do you want to discuss technical features with our Technology Team?

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se