LUMA has establish itself as a leading suppler of gold-plated wire for the antenna industry which designs and manufactures satellite systems for, near-Earth orbit applications in space. By providing high-quality wires, primarily gold-platedMolybdenum wire, LUMA has become a key supplier for manufacturers of communication and obeservation satellites worldwide.

The antenna industry represents LUMA’s fastest-growing application area, driven largely by project-specific demands, often linked to governmental initiatives. This sector is characterized by high production volumes, stringent quality standards, and comprehensive documentation requirements.

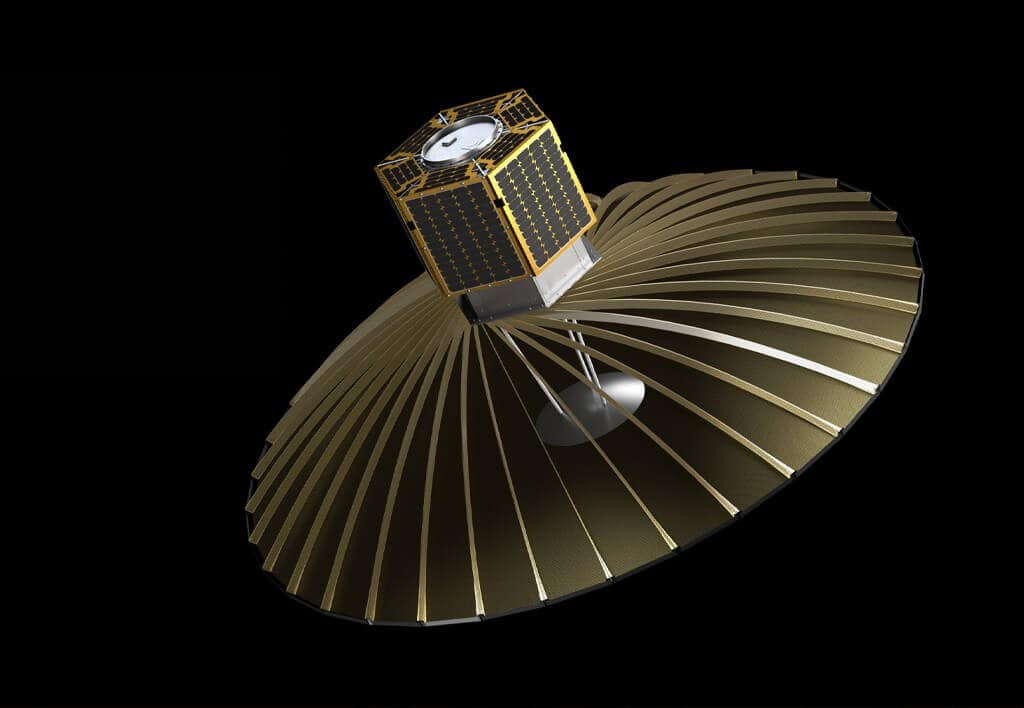

The primary product utilizing LUMA’s wire is the deployable reflector, a critical component in space antenna systems. Gold-plated Molybdenum and Gold-plated Tungsten wires are the predominant materials used for these applications. While alternative materials for reflector meshes (e.g., carbon, aramid, and nylon fibers) have been explored, gold-plated Molybdenum remains the preferred choice due to its exceptional properties.

Molybdenum is favoured as a base material due to its low density (10.22 g/cm³), making it approximately half the weight of Tungsten. This weight advantage is crucial during the launch phase of space missions, where every gram is critical.

Ulrik Palmqvist, Ph.D.

You are welcome to contact me when you need professional assistance

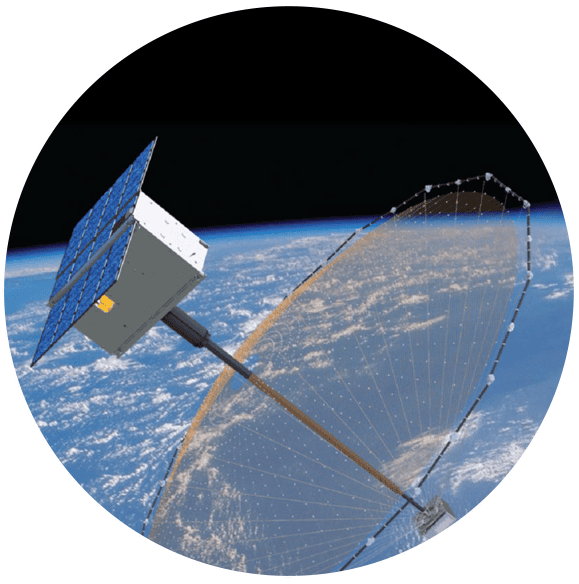

LUMA’s wire is warp-knitted by customers or subcontractors into a mesh structure—a combination of weaving and sewing techniques. These meshes, ranging in diameter from 1.5 meters to over 20 meters, are lightweight yet robust, with precise and repeatable deployable surface shapes.

For example, an antenna mesh measuring 19m × 17m when deployed can be compactly stowed to just 1m × 4m. Despite its lightweight structure, the mesh exhibits high stiffness, robust mechanical properties, and reliability.

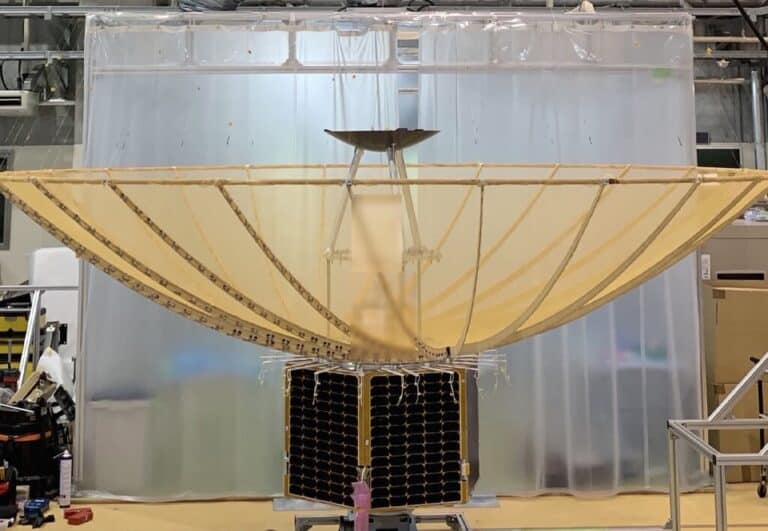

The warp-knitting process demands advanced expertise, particularly in mesh cutting, joining, tensioning, and shaping. LUMA’s wires meet strict requirements for dimensional consistency, tensile strength, and uniformity, ensuring their suitability for these demanding applications.

Gold-plated Molybdenum wire exhibits a combination of lightweight, elasticity, and thermal stability. Typical wire dimensions range from 20 to 40 microns. The wire withstands extreme environmental conditions, including thermal fluctuations, radiation, micrometeoroids, UV exposure, and atomic oxygen. The gold-plated layer, constituting at least 1% of the wire’s diameter, provides corrosion resistance and enhances RF signal reflection characteristics.

In a recent high-profile project, HPtex completed the inspection of a deployable antenna mesh built for ESA’s CIMR (Copernicus Imaging Microwave Radiometer) mission. The mesh is knitted using Luma Wire Tech’s ultra-fine wires.

The mesh construction is available in two versions, with either 20 µm or 25 µm high-purity metallic wire in a needle fineness of E32 (32 needles per inch). Each version forms a 10.2 × 9.5 m antenna mesh with an impressively low areal density of only ~40 g/m².

By combining our carefull controlled diameters, superior surface finish, and the ability to supply gold-plated or bare wire in this range, we help customers like HPtex and HPS meet both electromagnetic performance and structural / deployment reliability under stringent space conditions.

This collaboration showcases:

Learn more about our fine-wire capabilities for satellite systems and contact us to discuss how we can support your next mission.

How can we help you choosing the right wires for your application?

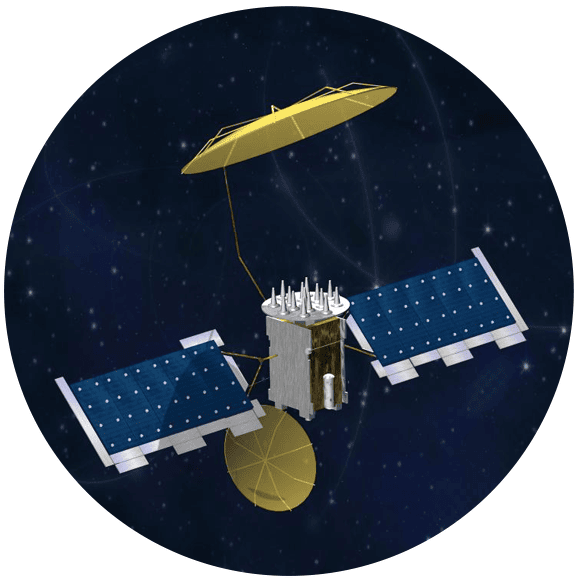

Satellite communication and observation antennas serve diverse applications, each with unique requirements:

V-band frequency is very high with 40-75 GHz. The higher frequencies are used the finer the mesh must be, the number of OPI (openings per inch) must be higher.

Large satellites (weight over 50 kgs) represent about a quarter of all satellites build and cover over 90 % of the generated turnover. Earth Observation is the most important field of use with approximately 50 % followed by telecom with 30-40 %. The business potential is huge and quickly growing. Learn more about Gold-plated Molybdenum Wires for Space Applications

The satellite industry is witnessing a shift toward higher frequency bands (Ka: 30–40 GHz, V: 40–75 GHz), necessitating finer mesh designs with increased openings per inch (OPI). Large satellites (>50 kg) dominate the market, representing approximately 90% of revenue. Key applications include Earth observation (50% market share) and telecommunications (30–40%).

Europe is investing heavily in space activities to reduce dependence on other global players, with initiatives such as the EU Copernicus program fostering advancements in deployable reflector systems. Despite the dominance of the U.S., European and private investments are rapidly increasing.

The demand for large reflectors (≥4 meters) is expected to grow, with a projected global market of 7–14 units annually over the next decade. Development timelines for larger antennas range from 4–5 years, emphasizing the need for consistent quality and long-term supplier reliability.

The rise of private investment, such as initiatives for global satellite internet networks, is driving additional demand. These networks rely on thousands of smaller satellites in low Earth orbit to deliver broadband connectivity to remote areas, offering a cost-effective alternative to terrestrial fiber infrastructure.

USA is the worldwide leading player for Satellite Antenna systems in Space. But Europe is investing heavily trying to reach an independency in Space Activities.

EC co-funded activity on LEA (Large European Antenna), followed by LEOB (Large European Antenna for Earth Observation) in H2020 Program was the starting point for the development of the complete LDRS subsystem, cumulating in the selection of LDRS as reflector solution for the CIMR mission (EU Copernicus program) which will last until 2026-2028.

The United States remains the global leader in space technology, driven by a robust space industry and high governmental investment in programs such as NASA and private entities like SpaceX and Blue Origin. Europe, under initiatives like the EU Copernicus program, has been rapidly catching up, aiming to reduce dependence on non-European technology.

China has emerged as a major contender, showcasing significant advancements through programs like the Tiangong space station and its lunar exploration missions. India has also gained prominence, particularly with cost-effective missions like Chandrayaan and the Mars Orbiter Mission, demonstrating innovation with limited resources.

Russia, with its historical legacy in space exploration, continues to play a significant role but faces challenges due to economic constraints and increasing competition. These nations, along with others, are driving global advancements in space technology, highlighting the strategic importance of space exploration for scientific, commercial, and geopolitical purposes.

Luma Wire Tech’s fine wires are trusted in Earth observation, telecommunication, and deep-space missions. By combining lightweight strength with superior conductivity, our gold-plated molybdenum wires ensure antennas perform with precision where reliability is non-negotiable.

Case Study: Copernicus Program

For example, in the EU Copernicus project, deployable reflector meshes made from fine wires were chosen to ensure stable RF performance in orbit. Luma Wire Tech’s gold-plated molybdenum wires provided the combination of low weight, elasticity, and durability required to withstand the harsh conditions of space. This collaboration demonstrates how our fine wires enable mission success in one of Europe’s most ambitious Earth observation programs.

Ulrik Palmqvist, Ph.D.

You are welcome to contact me when you need professional assistance

Why are precision wires critical in reflector meshes?

Precision wires deliver ultra-low weight with dimensional stability, enabling accurate RF performance and long-term reliability in orbit. Their consistent geometry ensures predictable electromagnetic behavior, essential for high-gain antennas.

How do fine wires function in deployable reflector antennas?

They form the conductive mesh surface that packs compactly for launch and deploys precisely in space. The wire mesh supports both mechanical stability and excellent signal reflection across targeted frequency bands.

What advantages do metallic wires offer over fiber-based solutions?

Metallic wires, especially gold-plated molybdenum, provide superior RF conductivity, durability, and thermal stability. They maintain surface accuracy and reflective performance better than carbon or aramid fibers, with lower stowage volume and predictable deployment behavior.

Why is gold-plated molybdenum a preferred material for space applications?

It combines high tensile strength, thermal resistance, corrosion protection, and excellent conductivity. Gold plating prevents oxidation in the harsh space environment, while molybdenum delivers mechanical integrity at extreme temperatures.

How do fine wires withstand the harsh conditions of space?

Our wires are engineered for radiation resistance, thermal cycling, and mechanical fatigue. Surface treatments and precision coatings maintain conductivity and structural stability through launch loads, vacuum exposure, and extreme temperature shifts.

What mesh diameters and tolerances are available?

We offer ultra-fine diameters with strict dimensional tolerances and customizable plating thickness. Tailored specifications ensure optimal RF performance and structural consistency for mission-critical components.

Can Luma Wire Tech supply custom wire configurations for satellite programs?

Yes. We collaborate with engineering teams to deliver custom alloys, plating systems, tensile properties, and spooling formats aligned with satellite antenna and deployment architecture requirements.

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se