The smallest wires often determine the largest breakthroughs.

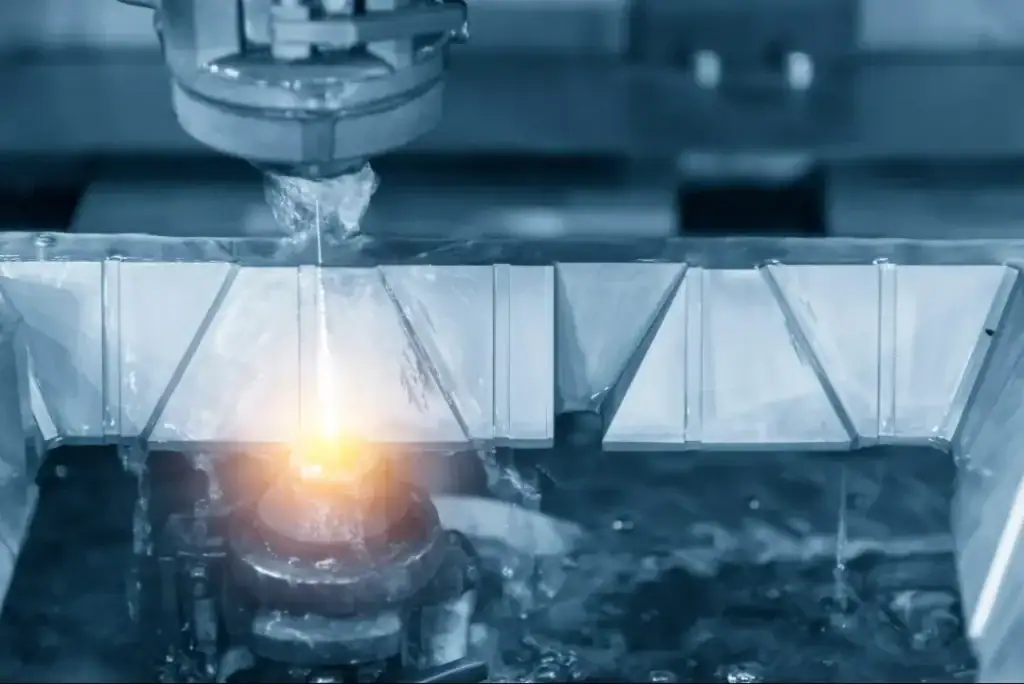

Wire cutting technology replaces conventional tools with fine wires to machine the hardest and most brittle materials. Therefore, cutting with fine wire has become an indispensable technique in industries where conventional tools reach their limits. Whether in Wire EDM (Electrical Discharge Machining) or in diamond and abrasive wire sawing, the ability to achieve micrometer precision depends on the performance of the wire itself. This is where fine wire for cutting technology becomes critical.

At Luma Wire Tech, we provide tungsten and molybdenum fine wires – cleaned, polished, or plated – as the technical foundation for OEM manufacturers who aim to develop the next generation of cutting wires. With expertise in advanced plating technologies such as nickel and gold, we enable tailored performance in collaboration with machine builders and process owners.

Ulrik Palmqvist, Ph.D.

You are welcome to contact me when you need professional assistance

In fine wire for cutting technology, Wire EDM represents one of the most precise and proven methods for machining ultra-hard materials. In Electrical Discharge Machining (EDM), a fine conductive wire acts as the tool, generating controlled electrical discharges that gradually erode the workpiece. The choice of wire material and diameter directly determines the balance between speed, accuracy, and stability.

Brass wires

The industry standard for general-purpose EDM. Brass combines good conductivity with reliable cutting speed, making it the default choice for most machine tasks. It is especially suitable for applications where productivity is more important than ultra-fine precision. Sometimes a zinc coating is added when throughput and process stability must be maximized.

Molybdenum wires

With high tensile strength and excellent straightness, molybdenum wires are particularly effective in applications requiring long, continuous cuts and repeatable accuracy. Manufacturers often use Molybdenum wires when stability under high tension is essential, for example in complex geometries or fine-feature machining.

Tungsten wires

Known for their exceptional stiffness and highest melting point of all metals (3,422 °C), tungsten wires are the preferred choice in micro-EDM and finishing operations. They excel in ultra-fine cutting where the manufactures require diameters below 30 μm, and where narrow kerfs, sharp corners, and precise contours matter more than cutting speed.

At Luma Wire Tech, we focus on tungsten and molybdenum fine wires engineered for demanding EDM applications:

By offering wires at the very limits of today’s EDM technology, we provide OEMs and process engineers with the foundation to push accuracy, stability, and surface quality further than conventional brass wires allow.

Diamond wire sawing is another key application area within fine wire for cutting technology, combining speed with exceptional edge quality. In diamond wire sawing (DWS), a fine core wire coated with diamond particles slices through hard and brittle materials such as silicon, sapphire, SiC (silicon carbide), and technical ceramics. The choice of core wire and its diameter directly determine kerf loss, surface quality, and process stability.

While high-strength steel dominates the market, tungsten cores are gaining interest in advanced R&D contexts, were stiffness and wire stability matter most. As studies on brazed diamond wires with tungsten cores suggest, the potential for enhanced cutting precision and grit stability is significant (ScienceDirect).

We provide tungsten fine wires in diameters between 5–300 μm, enabling OEMs and machine builders to explore the next generation of diamond wire solutions. Our advanced plating technologies use nickel which enhances bonding between the core and diamond particles, ensuring consistent grit exposure, longer tool life, and superior cutting performance. We welcome close collaboration with OEM manufacturers to co-develop customized wire solutions.

Abrasive wire cutting further expands the potential of fine wire for cutting technology, using a core wire combined with abrasive grains (such as silicon carbide, SiC, or alumina, aluminum oxide) or slurry to separate materials. While traditionally applied in foam, plastics, and softer composites, the technique is increasingly explored for harder and layered materials where conventional tools struggle.

We provide tungsten fine wires that can function as carriers for abrasives at ultra-thin dimensions, enabling OEMs to design cutting tools that move beyond traditional foam processing. By combining fine diameters with advanced surface treatments and plating, we help pave the way for abrasive wire cutting to enter entirely new fields of application. And we welcome collaboration with OEMs to co-develop the most effective solutions.

For OEM manufacturers, the foundation of any cutting-wire is consistency. Wire mechanics, geometry, and surface properties must remain stable from the first to the last meter of the spool. At Luma Wire Tech, we build quality assurance into every step of our production process:

Choosing Luma means gaining a development partner and not just a supplier of fine wire for cutting technology. We combine materials expertise with flexible production to support OEMs in creating the next generation of cutting wires and fine wires for cutting technology:

At Luma Wire Tech, we do not just deliver fine wires. We deliver a platform for OEMs to build cutting performance on, backed by traceable quality and a willingness to co-develop solutions for the future of wire-based machines.

At Luma Wire Tech, we recognize that the most significant advances in cutting technology happen when material expertise meets machine innovation.

Therefore, we are open and eager to establish partnerships with OEM manufacturers. By combining our knowledge in tungsten and molybdenum fine wires with the process insights of equipment builders and engineers, we can co-create wires that address the toughest cutting challenges.

From ultra-thin semiconductor wafer slicing to the precision machining of aerospace alloys, our fine wires are ready to become the backbone of tomorrow’s reliable and efficient processes, The leading source of fine wires for cutting technology.

The next generation of materials – harder, thinner, and more complex – demands a new generation of wires. At Luma Wire Tech, our expertise in metallurgy, advanced plating, and fine-wire manufacturing positions us to be the technical foundation for those developments.

We are looking to partner with OEMs who want to redefine what is possible in EDM, diamond wire sawing, and abrasive cutting. Together, we can push the boundaries of cutting technology, reduce kerf losses, and enable precision that was once out of reach.

How can we help you choosing the right wires for your application?

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se