When your core process depends on twisting multiple ultra-thin metal wires into a functional structure, every micron matters.

At Luma Wire Tech, we supply precision fine wire made of Tungsten and Molybdenum, engineered to perform reliably in high-precision twisting, stranding, braiding and cabling processes.

Whether you manufacture high-performance cables, braided or knitted mesh structures, composite conductors or technical textile yarns, our fine wire solutions are designed to behave predictably — spool after spool, batch after batch.

Our customers typically operate:

If your process involves continuous motion, constant tension and multiple contact points, the stability of the incoming fine wire is critical. This is where Luma Wire Tech makes a difference.

Ulrik Palmqvist, Ph.D.

You are welcome to contact me when you need professional assistance

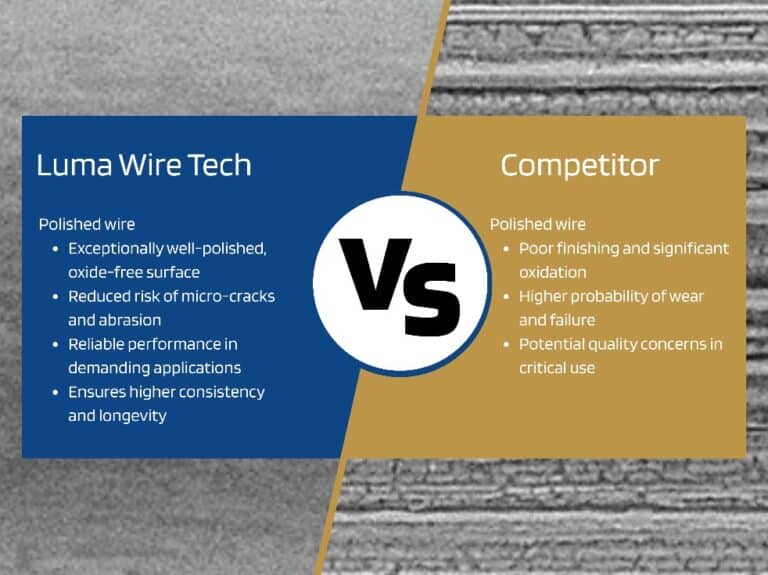

In twisting, braiding and stranding processes, wire surface quality directly affects friction, tension stability and wire breakage risk.

Luma precision fine wires feature exceptionally smooth, oxide-free surfaces to ensure stable interaction with guides, contact points and neighbouring wires.

The result:

For manufacturers running continuous wire-processing operations, surface integrity is a key factor in achieving repeatable, industrial-scale production.

At Luma Wire Tech, we focus on tungsten and molybdenum precision fine wires engineered for demanding EDM applications:

By offering wires at the very limits of today’s EDM technology, we provide OEMs and process engineers with the foundation to push accuracy, stability, and surface quality further than conventional brass wires allow.

For companies producing twisted, stranded or cabled fine wire structures, repeatability is essential.

Wire geometry, mechanical behaviour and surface properties must remain stable from the first to the last meter of the spool.

At Luma Wire Tech, quality assurance is built into every step of production:

This ensures predictable spool-to-spool behaviour and reliable performance in continuous twisting and stranding operations.

Applications such as braided metal elements and technical textiles are an active area of research in technical textile and wire integration, as explored by the RWTH Aachen University – Institute for Textile Technology (ITA)

Many of our customers do not sell wire as a product — they sell function, precision and reliability. Our role is to ensure the wire never becomes the limiting factor.

All parameters are aligned with your twisting geometry, tension levels and processing conditions.

In advanced twisting, braiding and stranding processes, there are rarely standard recipes. Small variations in wire diameter, surface condition or mechanical behaviour can significantly affect process stability, machine performance and final product quality.

We supply precision fine wire — without standard solutions.

Every delivery is based on a deep understanding of how the wire interacts with your equipment, tolerances and application requirements.

A technical dialogue with Luma Wire Tech focuses on:

How can we help you choosing the right wires for your application?

What is precision fine wire?

Precision fine wire refers to ultra-thin metal wire manufactured with tight dimensional tolerances, controlled mechanical behaviour and high surface quality. It is used in applications where wire performance directly affects process stability, repeatability and final product function, such as twisting, stranding, braiding and cabling operations.

Which materials does Luma Wire Tech offer for precision fine wire?

Luma Wire Tech specialises in Tungsten (W), Tungsten-Rhenium (W-Re) and Molybdenum (Mo) precision fine wire. These materials are selected for their high tensile strength, thermal stability and dimensional reliability in demanding wire-processing environments.

What wire diameters are available?

We manufacture precision fine wire in diameters from 4 to 300 microns (µm). Diameter selection, tolerances and geometry are adapted to suit the customer’s twisting, stranding or braiding process and tension requirements.

Why is surface quality important in twisting and stranding processes?

In continuous wire-processing operations, surface quality directly affects friction, tension stability and the risk of wire breakage. Smooth, oxide-controlled surfaces reduce abrasion in guides and contact points, enabling stable long production runs, higher uptime and lower scrap rates.

Do you offer gold-plated fine wire?

Yes. We offer gold-plated Tungsten and Molybdenum wire with controlled coating thickness, adhesion and porosity. Gold plating improves electrical conductivity, corrosion resistance and surface stability, and is optimised for continuous wire processing, not cosmetic appearance.

Are your wire solutions standard or customised?

We do not offer standard, off-the-shelf wire.

Each precision fine wire solution is custom-engineered based on the customer’s process conditions, including wire path geometry, tension levels, mechanical load and environmental requirements.

How do you ensure repeatability from spool to spool?

This ensures predictable wire behaviour from the first to the last meter of each spool.

Which applications use precision fine wire from Luma Wire Tech?

Our precision fine wire is used in: