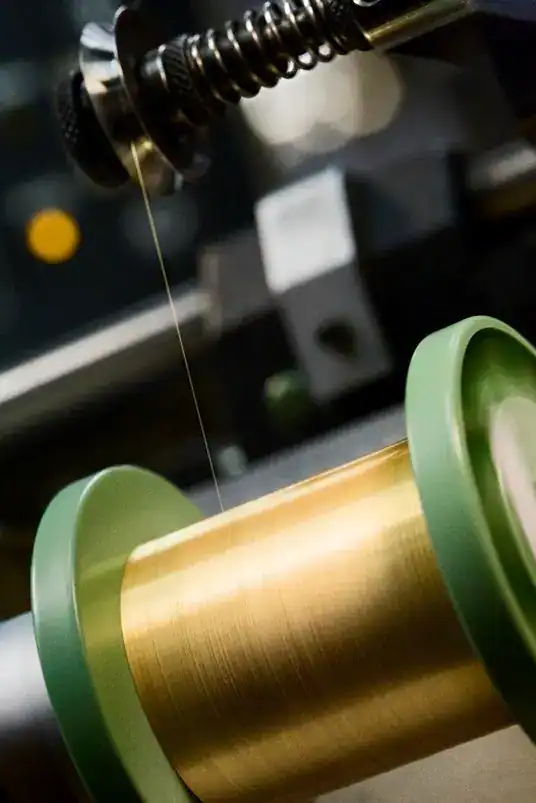

At Luma Wire Tech, we specialize in manufacturing ultra-fine wires from 4 to 300 microns, engineered for the most demanding applications. On this page you will find comprehensive fine wire technical product information and fine wire technical specifications covering our tungsten, molybdenum, and tungsten-rhenium wires. Depending on your requirements, wires are delivered cleaned or plated—with gold, nickel, silver, or platinum coatings available. Every spool, from a few hundred to several thousand meters, is produced under strict quality standards to ensure reliability in industries such as medical devices, electronics, aerospace, and advanced research.

This section of our fine wire technical product information explains why molybdenum is chosen for high-temperature and lightweight applications

This silvery metal has the sixth highest melting point among all metals, at 2,623°C. Its resistance to heat without expansion or softening makes it ideal for high-pressure, high-temperature applications.

Molybdenum wire is sometimes preferred over tungsten due to its lower density—about half that of tungsten—while still offering a high strength-to-weight ratio. Its light weight and high ductility make it the top choice for mesh wire in satellite antennas, a fact highlighted in our fine wire technical specifications. This application specifically requires gold-plated molybdenum wire.

Gold-plated molybdenum is also used in electronics. Besides corrosion resistance, the gold layer improves electrical contact and solder wettability – an important detail in our fine wire technical specifications . Common uses include connectors and electronic tubes.

Tungsten has the highest melting point of all metals at 3,422°C, making it ideal for demanding applications like light bulb filaments, rocket nozzles, and electrodes. As detailed in our fine wire technical product information, tungsten wire is also widely used in medical imaging and aerospace due to its density and X-ray visibility.

Its high density (19.25 g/cm³) allows for excellent absorption of radiation and X-rays, which is why it’s often used in medical guide wires for X-ray visibility.

With the lowest vapor pressure and thermal expansion of any pure metal, tungsten excels in power electronics and extreme environments such as jet propulsion applications frequently covered in our fine wire technical specifications. Above 1,650°C, it also has the highest tensile strength of any metal.

Gold plating on tungsten wire improves oxidation resistance and solderability, a feature emphasized in our technical product information for advanced industries. This makes it suitable for nuclear detectors, digital printing, medical devices, and technical textiles—any field requiring high stability and heat resistance.

Do you want to discuss technical features with our Technology Team?

The following table presents key specifications of tungsten, molybdenum, and tungsten-rhenium wires. These values are part of Luma’s official fine wire technical product information, provided to ensure engineers and researchers can select the right wire for their application.

| Base material | Diameter range** [µm] | Purity | UTS [N/mm2] | Rp 0,01* [N/mm2] | Elongation [%] | Surface treatment |

|---|---|---|---|---|---|---|

| Tungsten doped with K (W/K) | 4 – 300 | Min 99,95%W 60-65 ppm K | 2600 – 3500 | 1000 – 2000 | 1,5 – 3 | Electroetching Electropolishing Electroplating |

| Tungsten W (Re-3%) Available Soon | 4 – 300 | Min 97% W 3% Re | 2700 – 3900 | 1000 – 2000 | 1 – 2,5 | Electroetching Electropolishing Electroplating |

| Molybdenum ILQ doped with 0,03 % La2O3 | 10 – 300 | Min 99,9% Mo 0,03% La2O3 | 2100 – 2400 | 700 – 1400 | 1 – 2 | Electroetching Electroplating |

| ILQ Mo – after hydrogen annealing straightening | 10 – 300 | Min 99,9% Mo 0,03% La2O3 | 1700 – 2000 | 600 – 1200 | 1 – 2 | Electroetching Electroplating |

| Pure Mo – annealed | 10 – 300 | Min 99,97% Mo | 700 – 900 | 600 – 900 | ≥ 10% | Electroetching Electroplating |

*) Elongation automatically calculated by the software of the Tensile Strength machine.

**) Maximum plating diameter is approx. 200 μm.

| Abbreviation | Explanation |

|---|---|

| AAS | Atomic Absorption Spectroscopy |

| Au | Gold |

| E | Etched |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| K | Potassium |

| La2O3 | Lanthanum (III) oxide |

| LOM | Light Optical Microscopy |

| Mo | Molybdenum |

| Mo-ILQ | Microdoped molybdenum alloy with a lanthanum oxide |

| N/mm2 | Newton per Square Millimeter |

| Ni | Nickel |

| P | Polished |

| ppm | parts per million |

| R&D | Research and Development |

| Re | Rhenium |

| Rp0,01 | Point of plastical change (non-reversible) in wire structure under stress |

| RT | Room Temperature |

| SEM | Scanning Electron Microscope |

| UTS | Ultimate Tensile strength |

| W | Tungsten |

| W/K | Tungsten doped with Potassium |

| W/Re | Tungsten alloyed with Rhenium |

| µm | micrometers |

| Property | W/K – 60ppm |

|---|---|

| Thermal conductivity | + |

| Tensile strength and hardness | ≈ |

| High-temperature stability / Creep resistance | ≈ |

| Recrystallization temperature | ≈ |

| Workability/formability | ≈ |

| Corrosion resistance | ≈ |

| Wear resistance | + |

| Ductility | – |

| Electron work function | – |

| Electrical resistance | – |

| Property | ILQ Mo |

|---|---|

| Thermal and electrical conductivity | ≈ |

| Tensile strength | + |

| Stability at RT | ≈ |

| High-temperature stability / Creep resistance | + |

| Recrystallization temperature | + |

| Ductility after High-temperature use | + |

| Elongation Elongation compared to annealed Pure Mo | ≈ – |

| Weldability | + |

≈ comparable, + higher, – lower than pure Mo.

Our fine wire technical product information outlines a wide range of applications, from aerospace and medical technology to semiconductors and advanced R&D.

These application areas highlight how versatile Luma’s wires are, and why engineers worldwide rely on our technical product information to select the right solution for their projects.

Pure gold soft

According to MIL standard (2007): Type III (min 99.9 % purity); Grade A (max 90 Knoop).

Gold – increased hardness

According to MIL standard (2007): Type III (min 99.9 % purity); Grade B (max 91-129 Knoop).

| Material | Dimension < 50 µm | Dimension > 50 µm |

|---|---|---|

| W/K & W-Re wire | Coating thickness corresponds to 3 – 5% by weight as standard | 0.5 µm an standard |

| Mo wire | Coating thickness corresponds to 3 – 5% by weight as standard | 0.5 µm an standard |

As part of our comprehensive fine wire technical product information, we also provide full details of our in-house quality analysis and lab testing capabilities.

Each of these methods ensures that the properties listed in our fine wire technical specifications are verified and consistent across every batch.

By integrating advanced testing tools with detailedfine wire technical product information, Luma guarantees wires that meet the strictest industry requirements for safety and performance.

Please contact us if you have questions regarding our plating features and technology processes!

| Formulation | Examples of Application areas | Pros/Cons |

|---|---|---|

| W – Etched – Pure gold soft | Printers, Antennas, Instruments, Medical, Particle accelerators | Good adhesion |

| W – Polished – Pure gold soft | Particle accelerators, Research, Detectors | Limited adhesion. Can be used in the application where there is no mechanical impact on the wire |

| W – Etched – Gold increased hardness | Antennas, Research, Medical, Particle accelerators, Electronics, Scientific engineering | Good adhesion, Increased wear resistance |

| W – Polished – Nickel – Gold increased hardness | Medical Research, Medical | Improved adhesion, Increased wear resistance |

| Formulation | Examples of Application areas | Pros/Cons |

|---|---|---|

| W / Re – Etched – Pure gold soft | Research institute, Particle accelerators, Nuclear Research, Detector Technology | Good adhesion |

| W / Re – Polished – Pure gold soft | Particle accelerators | Limited adhesion |

| W / Re – Polished – Nickel –Gold increased hardness | Research, Printing, Antennas, Detectors | Improved adhesion, Increased wear resistance |

| W – Etched – Gold increased hardness | Detectors | Good adhesion, Increased wear resistance |

| Formulation | Examples of Application areas | Pros/Cons |

|---|---|---|

| Mo – Etched – Pure gold soft | Antennas, Research, Microchips | Good adhesion |

| Mo – Etched – Gold increased hardness | Antennas, Research, Medical, E-textiles | Good adhesion, Increased wear resistance |

| Mo – Etched – Nickel – Gold increased hardness | Antennas | Good adhesion, Increased wear resistance |

What diameters are available for Luma fine wires?

From 4 to 300 microns, with custom plating thicknesses on request.

Which base materials are used?

Primarily tungsten, molybdenum, and tungsten-rhenium alloys, with optional silver and copper.

What plating options for fine wires are offered?

The standard plating for wires with diameters ranging from 5 to 200 microns is gold and nickel, with additional options including silver, palladium, and platinum.

What industries use Luma’s fine wires?

Medical, aerospace, defense, electronics, space technology, and advanced R&D.

What does Luma’s fine wire technical product information include?

Our fine wire technical product information covers base materials such as tungsten, molybdenum, and tungsten-rhenium, along with detailed specifications on diameters, tensile strength, coatings, and plating options.

Why is fine wire technical product information important for engineers?

Engineers rely on fine wire technical product information to ensure the wires they choose meet strict performance and compliance requirements in industries such as aerospace, medical technology, electronics, and defense.

How does Luma guarantee accuracy in fine wire technical product information? All data in our fine wire technical product information is backed by extensive lab testing, including SEM, EDS, tensile strength analysis, and surface inspections. This guarantees consistent quality and reliable performance for every spool.

Can I request custom specifications not listed in the fine wire technical product information? Yes. Luma provides tailor-made wire solutions, and our Technology Team can adapt dimensions, coatings, and finishes beyond what is documented in the fine wire technical product information.

Is Luma Wire Tech ISO certified? Yes. Luma Wire Tech operates under strict quality management systems and is certified according to ISO, ensuring that our fine wire technical product information aligns with international standards for safety, traceability, and reliability.

Do you want to discuss details from our fine wire technical product information with our Technology Team? Contact us today for tailored guidance

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se