Antenna mesh for self-deployable satellites is a defining technology in today’s era of compact, high-performance space communication. Made from ultra-fine, gold-plated molybdenum wires, this lightweight mesh unfolds in orbit to create vast reflector surfaces with extreme RF precision. It replaces heavy solid reflectors, allowing satellites to transmit data globally while minimizing launch mass and maximizing efficiency. Engineered to withstand radiation, thermal cycling, and mechanical stress, antenna mesh for self-deployable satellites combines material science and aerospace engineering at its finest—transforming delicate wires into the backbone of next-generation reflector systems.

Why Antenna Mesh Matters in Self-Deployable Satellite Design

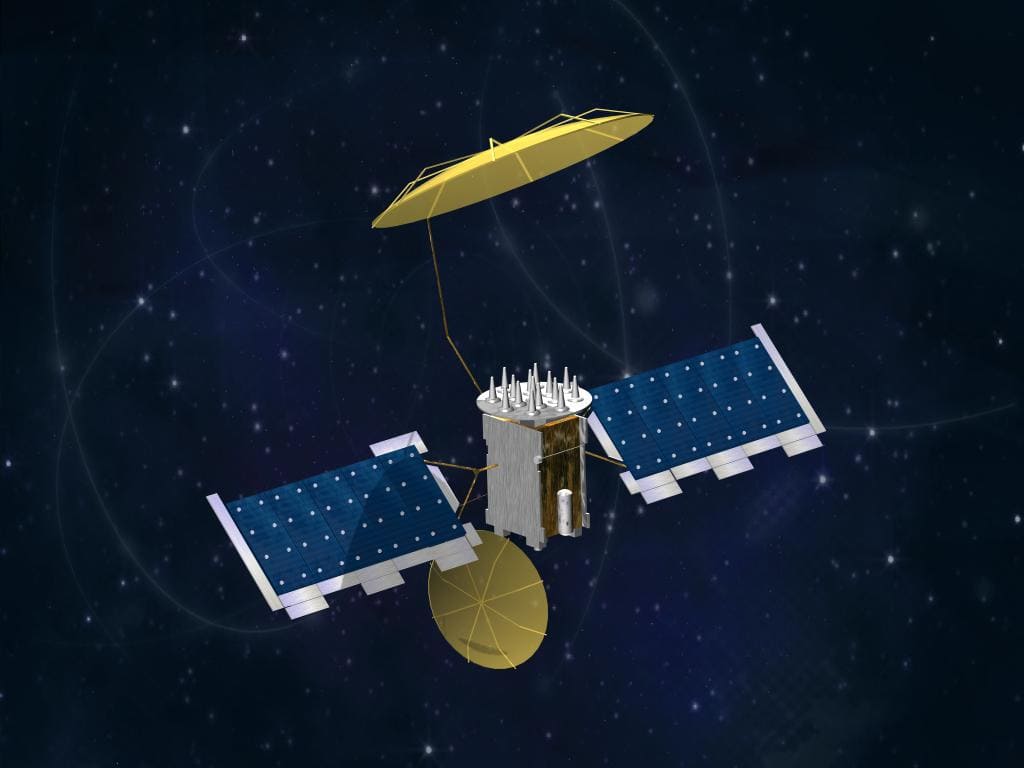

In modern space exploration and satellite communication, size matters. Large reflector antennas are needed to transmit data across continents, monitor Earth’s climate, and support space-based internet services. Yet rockets have limited payload space, forcing engineers to design self-deployable reflector antennas that can be compactly stowed during launch and precisely unfurled once in orbit.

At the heart of these systems lies a deceptively simple structure: antenna mesh for self-deployable antennas. Woven from ultra-fine metallic wires, this mesh forms the reflective surface that captures and directs radio frequency (RF) signals with extraordinary accuracy. Without it, the ambitious goals of next-generation satellites would remain grounded. (ESA – Deployable Antennas)

What Is Antenna Mesh for Self-Deployable Satellites?

Antenna mesh for self-deployable satellites is a lightweight, woven structure made from conductive fine wires. It replaces traditional solid reflectors by offering:

High reflectivity for RF signals (even at high frequencies).

Extreme compactness, allowing large antennas to fold into small volumes.

Mechanical resilience, maintaining geometric accuracy during deployment and in orbit.

In practice, a deployable mesh antenna may span over 20 meters in diameter yet fold down to a cylinder no wider than a few meters for launch. Once deployed, the mesh must hold its shape within millimeters to ensure signal precision.

Material Science Behind Space-Grade Mesh Wires

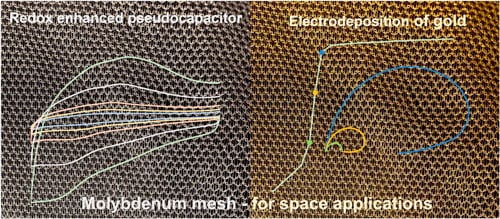

Our gold-plated molybdenum wires for space applications used in antenna mesh for self-deployable satellites and antenna reflectors.

Download our product brochure.

Why Gold-Plated Molybdenum Wire Is Ideal for Antenna Mesh

The performance of antenna mesh for self-deployable satellites depends heavily on the wire used. Engineers demand materials that are:

- Lightweight but strong – minimizing launch mass while resisting mechanical stress.

- Corrosion- and radiation-resistant – surviving the harsh vacuum of space

- Highly conductive – ensuring efficient RF reflection and low signal loss.

Historically, gold-plated molybdenum wire has been the leading for antenna mesh for self-deployable satellites. Molybdenum offers low density and high ductility, while gold plating adds corrosion protection and enhances reflectivity at radio frequencies. Alternatives like tungsten or advanced composites have been tested, but few match this balance of weight, strength, and conductivity (NASA – Gold-Plated Molybdenum Wire Mesh Reflector Tests, 1986)

Manufacturing Antenna Mesh for Self-Deployable Satellites

The creation of antenna mesh for self-deployable sattelites is far from simple textile weaving. Most manufacturers use warp-knitting or tricot-knit techniques, blending weaving and sewing methods to achieve a flexible yet stable structure.

Precision Weaving and Warp-Knit Technologies

Critical steps include:

- Wire diameter control – typically 20–40 microns, thinner than a human hair.

- Cutting and joining – ensuring seamless integration across massive reflector surfaces.

- Tensioning and shaping – maintaining dimensional stability so the deployed surface retains its precise parabolic form.

The result is a mesh that is lightweight yet remarkably stiff. For example, a 19 × 17 meter reflector mesh can be compacted into a 1 × 4 meter package for launch, and then redeployed in orbit with minimal surface error (NASA – Tricot-Knit Gold-Plated Molybdenum Wire Mesh, 1993).

Deployment and Structural Precision

The success of self-deployable satellite antennas depends on geometry. Even small deviations in mesh shape can distort RF signals, reducing performance. Engineers carefully design mesh panels (square, triangular, or hybrid facets) to minimize root-mean-square errors when stretched across large reflector frames (NASA – RMS Errors in Antenna Mesh Facets, 1989).

Deployment mechanisms use hinges, cables, and tensioning systems to ensure smooth unfolding. Modern designs employ pre-tensioned mesh and precision actuators to lock structures into place. Once deployed, the mesh surface must remain stable against vibrations, temperature cycles, and microgravity dynamics.

Enduring the Harsh Environment of Space

In orbit, antenna mesh for self-deployable satellites faces conditions far harsher than on Earth:

- Thermal cycling between –150 °C in shadow and +150 °C in sunlight.

- High-energy radiation that can weaken materials.

- Atomic oxygen and UV exposure degrading surfaces.

- Micrometeoroid impacts that threaten structural integrity.

Here, gold-plated fine wire meshes excel. The gold coating provides a corrosion barrier and ensures RF efficiency over years of continuous use. The molybdenum base contributes elasticity and thermal stability, enabling long service lifetimes even in extreme environments.

Trends Shaping the Future of Antenna Mesh Technology

The demand for higher-frequency communications is pushing antenna mesh technology into new territory.

- Ka-band and V-band systems (40–75 GHz) require finer mesh openings and tighter tolerances.

- Mega-constellations of satellites will need scalable, cost-efficient deployable reflectors.

- Earth observation satellites are using increasingly large antennas for applications like soil moisture mapping and biomass estimation (ESA Biomass Mission – 12 m Unfurlable Mesh Reflector).

- NASA’s NISAR mission demonstrates how deployable reflectors enable advanced radar imaging at global scales (NASA – NISAR Reflector Deployment, 2025).

These trends highlight the importance of both materials innovation and precision manufacturing in keeping up with next-generation requirements.

Case Studies - From Earth to Orbit

- NASA (N87-16021): Gold-plated molybdenum wire mesh reflectors tested for low transmission losses in RF systems.

- ESA Biomass Mission (2024): 12 m unfurlable reflector using woven conductive mesh, designed for Earth observation.

- NASA NISAR (2025): A giant deployable antenna successfully deployed in orbit to enable advanced radar imaging.

- Kamegai & Tsuboi (2012): Demonstrated performance of gold-plated molybdenum mesh at millimeter-wave frequencies (43 GHz) (arXiv – Metal Mesh Surface for Large Deployable Reflector).

- Li (2011): Analyzed electrical properties of wire mesh reflectors and how wire diameter and spacing affect RF efficiency (ScienceDirect – Electrical Properties of Wire Mesh Reflectors).

Luma Wire Tech´s Role in the Global Supply Chain

While antenna mesh design and deployment involve many aerospace partners, the story begins with wire. LUMA Wire Tech is the only European producer of gold-plated mesh wire for deployable reflectors. With over 90 years of expertise in fine wire manufacturing, LUMA delivers consistent quality in diameter tolerances, coating adhesion, and tensile strength—ensuring that the smallest components can withstand the vastness of space. Contact us

Conclusion – A Hidden but Essential Technology

The brilliance of a satellite’s antenna is not in its size or shape alone, but in the invisible precision of its woven mesh. Antenna mesh for self-deployable satellites is a marvel of engineering, transforming hair-thin wires into massive, reliable reflectors that bring data from orbit to Earth.

As communication frequencies climb higher and the demand for global connectivity grows, antenna mesh will remain one of the most critical—and least visible—technologies in space exploration. And with materials like gold-plated molybdenum wire at its core, it is poised to meet the challenges of the future.

How can we help you choosing the right wires for your application?