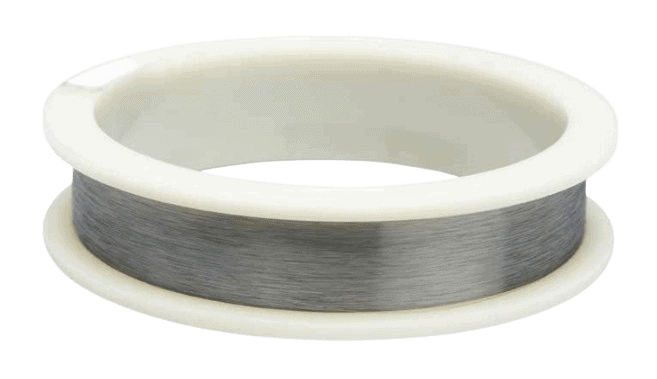

At Luma Wire Tech, we manufacture molybdenum wires between 10 and 300 microns in diameter, designed for applications where lightweight strength and high ductility are essential. Molybdenum offers about half the density of tungsten while maintaining impressive thermal stability and tensile strength.

Our cleaned molybdenum wires are trusted in space, electronics, and scientific applications where plated surfaces are not required. Produced in Sweden under ISO-certified standards, these wires deliver reliability and consistency to advanced industries worldwide.

High melting point (2,623°C) and excellent thermal stability

About 50% lighter than tungsten, reducing weight in critical applications

Superior ductility and formability for fine mesh structures

Stable performance in high-pressure and high-temperature environments

Ideal for applications where plating is not necessary

Gold, Silver, Palladium and Platinum on request

Aerospace

Lightweight mesh antennas

Medical

Neurostimulation

surgical robotics

Sensors

R&D instrumentation

Electronics

Wire bonding – microchips

fine wire for technical research and development

fine wire for technical textiles

fine wire for digital printing and ion generators

Fine wire for lightning industry

Do you want to discuss technical features with our Technology Team?

Molybdenum’s lightweight yet strong structure has made it a critical material in modern aerospace and automotive applications. Its global importance is reflected in production and consumption trends reported by the USGS

Choose Luma Wire Tech’s cleaned molybdenum wire for lightweight strength and reliable performance in demanding applications Contact us

How can we help you choosing the right wires for your application?

What is cleaned molybdenum wire?

High-purity molybdenum wires that has been surface-treated to remove oxides and impurities. The result is a smooth, contamination-free wire suitable for demanding industrial and scientific applications.

Why choose cleaned molybdenum wire instead of untreated wire?

Cleaned molybdenum wire provides superior surface quality, better conductivity, and improved reliability. It ensures consistent performance in aerospace, electronics, and medical devices where even minor impurities can cause failure.

What industries use molybdenum wire?

It is widely used in aerospace (satellite meshes and structural components), electronics (semiconductors, connectors), medical devices (stents, surgical tools), and R&D (detectors, high-precision instruments).

What diameters are available for these wire?

Luma Wire Tech supplies molybdenum wire in dimensions from 10 to 300 microns, tailored to customer-specific requirements.

How is molybdenum wires manufactured at Luma Wire Tech?

Our wires are produced in Sweden under strict ISO-certified processes, ensuring consistent quality, full traceability, and compliance with international standards.

Can molybdenum wires be customized?

Yes. We offer customized dimensions, spooling options, and integration support to meet the exact specifications of your project.

Is cleaned molybdenum wire corrosion-resistant?

Molybdenum has natural resistance to heat and wear. For environments with high oxidation or corrosion risk, gold-plated molybdenum wire may be recommended.

Do you want to discuss technical features with our Technology Team?

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copy text

in text editor

field here.

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se