In the space industry, there is no room for error. Materials must be lightweight, reliable, and able to withstand the harshest conditions imaginable. At Luma Wire Tech, we deliver gold-plated molybdenum wires for space applications that provide the durability and stability required where performance cannot fail.

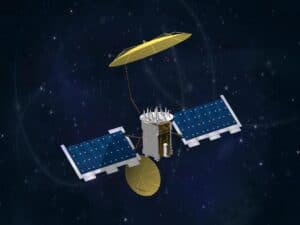

Alongside these, we also offer ultra-fine tungsten wires for highly specialized tasks, ensuring flexibility for diverse mission needs. From self-deployable satellite antennas to thermal sensors and high-frequency signal pathways, our precision fine wires combine low weight, superior conductivity, and unmatched reliability—enabling spacecraft to perform flawlessly in orbit.

Trusted worldwide, Luma’s precision molybdenum wires for space are the foundation of deployable reflector meshes, advanced antennas, and thermal management systems.

How can we help you choosing the right wires for your application?

Every mission into orbit demands materials that perform flawlessly under extreme conditions. That is why leading satellite manufacturers choose Luma . Our gold-plated molybdenum wires for space applications deliver the perfect balance of strength, low mass, and conductivity—making them the backbone of deployable reflector meshes, antennas, and advanced communication systems.

Here are the key advantages that set our wires apart:

Luma’s gold-plated molybdenum wires for space applications are designed to combine elasticity with exceptional tensile strength. They withstand the violent stresses of launch, the precision demands of deployment, and decades of fatigue in orbit—while preserving structural integrity in warp-knitted reflector meshes spanning up to 20 meters in diameter.

Space is an unforgiving environment, exposing materials to extreme temperature shifts, UV radiation, and atomic oxygen. Our gold-plated molybdenum wires for space applications are engineered to resist these harsh conditions without degradation. The protective gold plating prevents corrosion and ensures stable performance throughout long-duration missions.

In aerospace engineering, weight is mission-critical. By using gold-plated molybdenum wires for space applications, engineers can design deployable reflector meshes that fold into ultra-compact volumes for launch, then expand flawlessly once in orbit. A 19 × 17 meter mesh, for example, can be stowed in just a 1 × 4 meter package while preserving its surface accuracy and RF performance.

As satellite communication advances into higher frequency bands, including Ka- and V-band (40–75 GHz), reflector meshes must deliver uncompromising signal quality. With Luma’s extreme diameter control, gold-plated molybdenum wires for space applications guarantee consistent RF reflection and minimal signal loss, even at the highest frequencies. This makes them the preferred solution for next-generation communication satellites.

Deployable reflector antennas are at the heart of modern satellite communication, and their performance depends on the quality of the materials used. Our gold-plated molybdenum wires for space applications provide the strength, elasticity, and precision required to build meshes that function flawlessly in orbit.

Luma’s reflector meshes, ranging from 1.5 to over 20 meters in diameter, combine lightweight construction with mechanical stability. They can be compactly folded for launch and then expand into their exact geometry once deployed, ensuring consistent RF performance across Ku-, Ka-, and V-band frequencies. This balance of low mass and high durability makes Luma the trusted choice for next-generation satellite reflector systems.

Our fine wires support satellites dedicated to monitoring soil moisture, vegetation biomass, and climate indicators with unmatched accuracy. By integrating gold-plated molybdenum wires for space applications, Earth observation missions achieve reliable data collection even under extreme thermal cycling and radiation exposure. This ensures long-term consistency for global climate studies and sustainability programs.

As demand for global broadband grows, thousands of satellites are being launched into low Earth orbit. Luma’s precision wires power this new generation of connectivity by delivering stable RF performance for high-capacity telecommunication satellites and space-based internet constellations. The use of gold-plated molybdenum wires for space applications guarantees that these systems maintain signal integrity and provide seamless global coverage.

Extreme thermal cycles in space require materials that can expand and contract without failing. Our gold-plated molybdenum wires for space applications are engineered for resilience under these conditions, providing both thermal sensors and lightweight structural support that maintain integrity throughout years of orbital operation

With the shift to higher frequency bands such as Ka- and V-band, RF precision is critical. Our gold-plated molybdenum wires for space applications ensure consistent conductivity and low signal loss, supporting advanced communication systems where failure is not an option.At V-band frequencies, precision is critical. That’s why gold-plated molybdenum wires for space applications are trusted to maintain RF stability across next-generation satellite constellations.

Luma has become the first choice for deployable reflector meshes among leading satellite antenna manufacturers worldwide. Our gold-plated molybdenum wires for space applications combine elasticity, tensile strength, and corrosion resistance—qualities that are mission-critical in orbit.

Engineers rely on Luma’s wires to design reflectors that are not only lightweight but also capable of maintaining sub-millimeter precision after deployment. This accuracy ensures that large reflector meshes—from 5 meters up to 20+ meters in diameter—deliver consistent RF performance across Ku-, Ka-, and even V-band frequencies.

Unlike alternative materials such as carbon or aramid fibers, gold-plated molybdenum wires for space applications provide a unique balance of low mass and long-term durability. The gold plating enhances conductivity and protects against harsh space conditions, including atomic oxygen, UV radiation, and extreme thermal cycling.

With over 90 years of expertise, Luma has established itself as a trusted supplier for space missions where failure is not an option. Our reflector mesh solutions, powered by gold-plated molybdenum wires for space applications, support everything from Earth observation satellites to next-generation telecommunication systems and global broadband constellations.

For decades, Luma Wire Tech has been a trusted partner to aerospace and defense leaders who demand absolute reliability. Our gold-plated molybdenum wires for space applications stand out because they deliver performance where every detail matters.

Exclusive European Supplier – Luma is the only company in Europe with the capability to plate molybdenum wires below 10 microns, giving satellite manufacturers access to a unique and critical resource.

Extreme Diameter Control – Our advanced production ensures uniformity across thousands of meters of wire, guaranteeing stable RF reflection in large deployable reflector meshes.

Surface Perfection – Electro-polished finishes reduce micro-cracks and prevent particulate release in vacuum environments, enhancing durability in long-duration missions.

Proven Durability – With corrosion and radiation resistance built into every wire, Luma solutions withstand decades of exposure in orbit.

Custom Engineering – From ultra-thin diameters for high-frequency signal pathways to mission-specific coatings, we collaborate closely with clients to meet unique design challenges.

Global Expertise – With more than 90 years of wire manufacturing experience, Luma has supplied some of the world’s most demanding projects, including satellite antennas, Earth observation systems, and telecommunication constellations. Through partnerships with organizations like Big Science Sweden, our solutions are reaching new research facilities and space missions.

This combination of technical precision, unmatched reliability, and proven heritage makes Luma the supplier of choice for space missions where performance cannot fail.

Why is gold-plated molybdenum wire preferred for satellite antennas?

Because it offers the perfect balance of low mass, elasticity, and corrosion protection. This makes gold-plated molybdenum wires for space applications the first choice for large deployable reflector meshes, ensuring both lightweight performance and long-term durability.

How does wire diameter impact RF performance in space?

At higher frequencies such as Ka- and V-band, reflector meshes require finer wires with precise spacing. Luma’s extreme diameter control guarantees consistent RF reflection and minimal signal loss, enabling reliable communication across the most advanced satellite systems.

What makes Luma Wire Tech different from other suppliers?

We are the only European supplier of gold-plated molybdenum wires for space, offering unmatched surface quality and plating expertise. Learn more about how ESA – European Space Agency sets requirements for materials used in space systems.

Can Luma customize gold-plated molybdenum wires for unique missions?

Yes. We work closely with satellite manufacturers and research institutions to supply mission-specific diameters, coatings, and finishes. Whether for reflector meshes, thermal sensors, or signal pathways, our wires are tailored to exact requirements.

How do Luma wires contribute to reducing launch costs?

By minimizing mass while maintaining structural strength, gold-plated molybdenum wires allow larger reflector systems to be folded into compact volumes during launch. This enables engineers to optimize payload efficiency and reduce mission costs.

Which satellite applications rely most on Luma wires?

Our wires are widely used in Earth observation satellites, telecommunication constellations, and broadband internet systems. They are also integral to thermal sensors, high-frequency pathways, and structural components exposed to extreme space environments

For more than nine decades, Luma Wire Tech has supplied precision wire solutions for industries where failure is not an option. Today, our gold-plated molybdenum wires for space applications are trusted by leading satellite manufacturers, research institutions, and aerospace pioneers worldwide.

Whether your project involves deployable reflector meshes, high-frequency communication systems, or advanced Earth observation satellites, Luma delivers the expertise, customization, and reliability needed for mission success.

Contact us today to discuss your requirements and discover how Luma can become your trusted partner and and ensure your mission benefits from the proven reliability of gold-plated molybdenum wires for space applications.

How can we help you choosing the right wires for your application?

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se