Medical technology relies on materials that are both reliable and precise. Among the smallest but most important are gold-plated tungsten wires for medical devices, used in stents, guide wires, catheters, electrosurgical tools, and imaging systems. At Luma , our gold-plated tungsten wires for medical devices are engineered with micron-level accuracy, delivering unmatched surface finish and performance in life-critical applications. By combining tungsten’s natural strength with protective gold coating, we provide wires that deliver consistent performance in life-critical applications.

For decades, we have supported the medical industry with specialty wires that meet the strictest standards of quality and safety. Every wire is manufactured under controlled conditions in Sweden, ensuring full traceability and compliance with international regulations. This commitment gives our customers confidence that the components they integrate into life-saving devices are not only technically advanced but also ethically and responsibly produced.

Here are five reasons why leading medical device manufacturers choose gold-plated tungsten wires for medical devices.

When it comes to life-saving medical technology, materials must deliver absolute precision and reliability. That is why leading manufacturers rely on Luma’s gold-plated tungsten wires for medical devices. Combining tungsten’s exceptional strength with the protective benefits of gold plating, these wires enable safer, smaller, and more effective devices.

From cardiovascular stents and guide wires to imaging systems and electrosurgical tools, they form the backbone of modern healthcare innovations. Below are five key reasons why they are the material of choice for advanced medical engineering.

One of the main reasons to use gold-plated tungsten wires for medical devices is their radiopacity. Tungsten’s density (19.3 g/cm³) makes it highly visible under X-ray.

This ensures that guide wires, stents, or coils can be accurately tracked inside the body during minimally invasive procedures. For surgeons, visibility is safety, and radiopaque wires reduce risk, improve precision, and shorten procedure times.

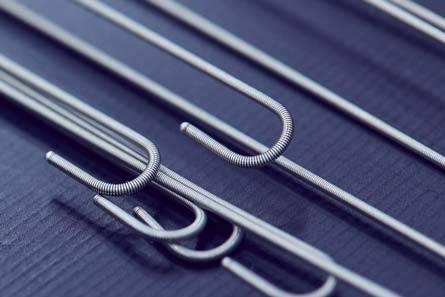

Another key advantage of gold-plated tungsten wires for medical devices is their ability to remain strong even at ultra-fine sizes. Tungsten maintains exceptional tensile strength at diameters as small as 5 microns, enabling engineers to design miniature devices that perform reliably.

From spring coils to surgical baskets, our wires deliver the strength and flexibility needed to support the trend toward less invasive treatments

Gold plating adds a protective barrier, turning tungsten into a medical-grade wire solution. This coating prevents corrosion, enhances ductility, and improves handling during device assembly.

By choosing gold-plated tungsten wires for medical devices, manufacturers gain both long-term reliability and easier integration into complex designs. At Luma, we offer custom plating options tailored to the specific needs of each application.

The versatility of gold-plated tungsten wires for medical devices is unmatched. They are found in:

Guide wires & catheters for safe vascular navigation

Stents & coils for minimally invasive cardiovascular treatments

Electrosurgical electrodes hat withstand high heat without deformation

Retrieval baskets & snatchers woven from ultra-fine wire for safe surgical extraction

Imaging and therapy equipment, including proton beam systems and detectors

This broad range of applications makes them indispensable in modern healthcare.

Luma’s gold-plated tungsten wires for medical devices are trusted by research institutions and manufacturers around the globe. We support projects in neurosurgery, such as deep brain stimulation electrodes, as well as innovations in diagnostics and biodegradable implants. Our wires help pioneers push the limits of what is possible in medical technology, ensuring that the next generation of devices is safer, more effective, and more precise.

We also collaborate closely with design engineers during the development phase, offering guidance on selecting the right wire dimensions, coatings, and tolerances for each application. This partnership approach allows our customers to move from concept to production more quickly, reducing development costs and accelerating time-to-market. Whether for large-scale production or specialized prototypes, Luma provides the expertise and flexibility needed to succeed.

Ulrik Palmqvist, Ph.D.

You are welcome to contact me when you need professional assistance

Wires from 5 to 150 microns – precision-engineered for medical devices.

Custom plating options – platinum, palladium, nickel, or silver.

Decades of medical wire expertise – trusted by global manufacturers.

Commitment to quality & compliance – aligned with ISO and international standards.

European manufacturing excellence – produced in Sweden under strict ESG principles.

Superior surface finish – industry-leading smoothness for safe device integration.

Why is tungsten used in medical devices?

Because of its density, strength, and radiopacity, tungsten is ideal for stents, catheters, and guide wires.

What advantage does gold plating add?

Gold plating prevents corrosion, improves ductility, and ensures safe long-term performance in the body.

Can Luma provide custom wire dimensions?

Yes, we produce wires from 5 to 150 microns, with custom plating options and tolerances for specific applications.

Where are Luma’s medical wires produced?

All gold-plated tungsten wires for medical devices are manufactured in Sweden under strict ESG and sustainability standards.

Copyright © Luma Wire Tech 2018

Powered by: Aditor.se